- Needle Valve

Series- Mini Hard Seat Needle Valves-100 Series

- Mini Soft Tip Needle Valve-150 Series

- Multiport Hard Seat Needle Valve-200 Series

- (304 & 30604 Models) Multiport, Soft Seat Needle Valve

- Standard, Hard Seat Needle Valve (400 series)

- Standard, Soft Seat Needle Valve (500 series)

- Block & Bleed Hard Seat Needle Valve (600 series)

- Block & Bleed Soft Seat Needle Valve (700 series)

- Bleed Hard Seat & Soft Tip Needle Valve (800/850 series)

- 2070 Series 2-Valve Block & Bleed, Hard Seat Needle Valve

- 2170 Series 2-Valve Block & Bleed, Soft Seat Needle Valve

- 3070 Series 3-Valve Double Block & Bleed, Hard Seat Needle Valve

- Manifold Valve Series

- Direct Connect Assembly

- Connector

- Transducer

Series- Voltage Output Pressure Transducer (200 Series)NOSHOK

- Compact Pressure Transducer OEM (300 series)

- Heavy High Accuracy H-Duty Pressure Transducer (615/616 series)

- High Volume OEM Pressure Transducer (650 series)

- High Performance Micro-Size Transducer (660 series)

- Submersible Level Transducer (612 series)

- Cage-Protected Submersible Level Transmitter (613 series)

- Precision Heavy Duty Pressure Transducer (640 series)

- Small Diameter Submersible Level Transmitter (611 Series)

- Transducer 200 Series by PSI

- Transmitter

Series- NOSHOK 100 SERIES Current Output Pressure Transmitter

- Explosion-Proof Pressure Transmitter NOSHOK (621-622 Series)

- Non-Incendive Pressure Transmitter (623-624 Series)

- Intrinsically Safe Pressure Transmitter (625/626 Series)

- Intrinsically Safe Hammer Union Pressure Transmitter (628 series)

- Electronic Indicating Temperature Transmitter/Switch (850 Series)

- Electronic Indicating Pressure Transmitter/Switch 800 SERIES

- 11 Series ASME-BPE Sanitary Clamp Pressure Transmitter

- Homogenizer Sanitary Pressure Transmitter (21 Series)

- Intrinsically Safe Submersible Liquid Level Transmitter (627 series)

- Intelligent Pressure & Level Transmitter (Noshok 25 Series)

- SNORKEL” Pressure & Level Transmitter-Noshok 30 Series”

- Digital Temperature Indicators, Battery Powered Noshok 822/823 Series

- Small Diameter Submersible Level Transmitter (Noshok 611 Series)

- Industrial RTD, Probe Type with Connection Head Noshok 910/915 Series

- Transmitter 100 series by PSI

- Seal

Series- Type10H Standard & Elevated Pressure, Bolted, Replaceable Diaphragm Seal

- Type 10L Reduced Pressure, Non-Metallic Lower, Bolted, Replaceable Diaphragm Seal

- Type 5 All Non-Metallic, Non-Replaceable Diaphragm Seal

- Type 12 Sanitary, Clamped-Style, ASME-BPE, Non-Replaceable Diaphragm Seal

- Type 20 Front Flush, Non-Replaceable Diaphragm Seal

- Type 25 Standard & Elevated Pressure, Non-Replaceable Diaphragm Seal

- Type 29 High Volumetric Displacement, Non-Replaceable Diaphragm Seal

- Type 30/30H Standard & Elevated Pressure, Bolted, Non-Replaceable Diaphragm Seal

- Type 30L Reduced Pressure, Non-Metallic Lower, Bolted, Non-Replaceable Diaphragm Seal

- Type 10 Standard & Elevated Pressure, Bolted, Replaceable Diaphragm Seal

- Type 25H Standard & Elevated Pressure, Non-Replaceable Diaphragm Seal

- Gauge

Series- ABS & Steel Case Dry Pressure Gauge 100 series

- Low Pressure Diaphragm Dry Pressure Gauge 200 series

- Brass Liquid Filled Gauge (300 series)

- All Stainless steel Dry gauge (400 series)

- All Stainless Steel Liquid Filled Gauge (500 series)

- Process Pressure Gauge (600/700 series)

- Precision Test dry Gauge (800 series)

- Digital Gauge NOSHOK (1000 series)

- Differential gauge

- Digital Meter Indicator Series

- Thermometer Gauge series

- Digital Temperature Indicator (820/821 Series)

- Digital Meter Indicator Series

- Extreme High Pressure Gauge Dry & Liquid Filled 402/502 Series

- 25-911-Series 1/4″ NPT Back Conn 2’5 SS Liquid Filled Pressure Gauge

- Manifold Valve

Series - Switch

Series- 100 Series Mechanical Compact SPST Pressure Switch

- Mechanical Compact Switch -200 series

- Compact SPDT Mechanical Switch With Adjustable Hysteresis -300 Series

- Heavy-Duty Mechanical Switch-400 Series

- Electronic Indicating Pressure Transmitter/Switch-800 Series

- Noshok 850 series Electronic Indicating Temperature Transmitter/Switch

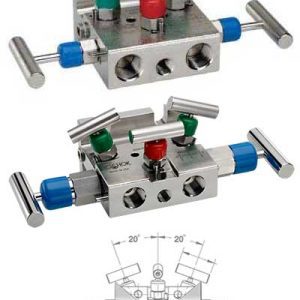

NOSHOK 5132-MFC-FP FLARE PATTEREN Soft Seat, Flange x 1/4 NPT Female, Steel 5-Valve Natural Gas Manifold Valve

$402.06 Original price was: $402.06.$299.99Current price is: $299.99.

Noshok 2170-MFS-PK1 PEAK ADDER 1/2 NPT, Male x Female, 316 SS Soft Seat/Tip 2-Valve Block & Bleed

$332.65 Original price was: $332.65.$249.58Current price is: $249.58.

NOSHOK 5130-MFS-PK1 Peek seat Soft Seat Flange x 1/2 NPT Female, 316 SS 5 Gas Manifold Valve

Part Number:

5130-MFS-PK1

$621.16 Original price was: $621.16.$419.14Current price is: $419.14.

14

People watching this product now!

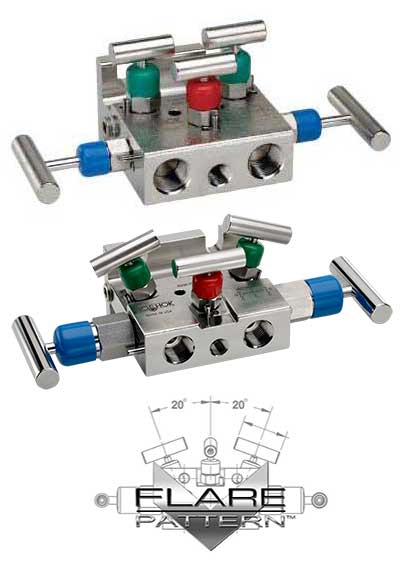

Noshok 5130-MFS-PK1 Peek seat Soft Seat Flange x 1/2 NPT Female, 316 SS 5 Gas Manifold Valve

Gas Manifold Valve

Designed for use with differential pressure transmitters incorporating two isolation valves, two equalizing valves and a vent valve required in natural gas applications

Flare Pattern™ valve configuration provides maximum clearance for fingers during operation

Soft tip valves feature a patented Acetal non-rotating soft tip stem, and a back-up metal-to-metal seal (U.S. Patent 6,820,857)

Available in block, single flange, or double flange connection for remote or direct installation

100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

5030 Series hard seat valves have 10,000 psi pressure rating @ 200 °F

5130 Series soft seat/tip valves have 6,000 psi pressure rating @ 200 °F

5130 Series valves also feature a replaceable Acetal seat, and straight through porting for bidirectional, high capacity flow and easy roddable cleaning on the block valves

Blow-out proof stem provides a secondary stem seal in the full open position

FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

All stems are 316 Stainless Steel

All stem threads are rolled for strength and ease of operation

One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

Slotted spring pin to prevent accidental loosening

Vinyl dust caps for bonnets and stems (non-packing)

Patented body-to-bonnet, metal-to-metal seal is designed to significantly increase the pressure

ORDERING INFORMATION

| SERIES | 5 | 5-valve | ||||

| SEATS | 0 | Hard seat | 1 | Soft seat/tip | ||

| PROCESS TYPE | 3 | Natural gas flow | ||||

| CONNECTION | 0 | 1/2″ NPT or flange | ||||

| VALVE TYPES | MFC | Flange-Female, Steel | MFS | Flange-Female, Stainless Steel | MMC | Flange-Flange, Steel |

| FFC | Female-Female, Steel | FFS | Female-Female, Stainless Steel | MMS | Flange-Flange, Stainless Steel |

ORDERING INFORMATION – Additional Options

| BODY CONFIGURATION | FP | Flare Pattern™ | ||||||

| SOFT SEATS | PK1 | PEEK | KF1 | PCTFE | ||||

| PACKINGS† | P1 | PTFE | P2 | Graphite ** | ||||

| STEM TIPS | T1 | Non-rotating (316 stainless)** | T4 | PEEK*** | T7 | Ball (ceramic)** | T10 | Regulating Acetal*** |

| T2 | Acetal*** | T5 | Ball (440C stainless)** | T8 | Ball (Monel)** | T11 | Regulating PTCFE*** | |

| T3 | PTCFE*** | T6 | Ball (carbide)** | T9 | Non-rotating regulating (316 Stainless)** | T12 | Regulating PEEK*** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Perfluoroelastomer) | NB1 | NBR | ||

| HANDLES | HL1 | 1-13/16″ Mini “T” | HL4 | 1-3/8″ Phenolic | ||||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For 5030 only.

*** For 5130 only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are isolation “T” handles (HL2) and equalizing & vent 1-3/8″ mini “T” handles (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, handles on the 5130-MFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.

Be the first to review “Noshok 5130-MFS-PK1 Peek seat Soft Seat Flange x 1/2 NPT Female, 316 SS 5 Gas Manifold Valve” Cancel reply

Description

Noshok 5130-MFS-PK1 Peek seat Soft Seat Flange x 1/2 NPT Female, 316 SS 5 Gas Manifold Valve

Gas Manifold Valve

Designed for use with differential pressure transmitters incorporating two isolation valves, two equalizing valves and a vent valve required in natural gas applications

Flare Pattern™ valve configuration provides maximum clearance for fingers during operation

Soft tip valves feature a patented Acetal non-rotating soft tip stem, and a back-up metal-to-metal seal (U.S. Patent 6,820,857)

Available in block, single flange, or double flange connection for remote or direct installation

100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

5030 Series hard seat valves have 10,000 psi pressure rating @ 200 °F

5130 Series soft seat/tip valves have 6,000 psi pressure rating @ 200 °F

5130 Series valves also feature a replaceable Acetal seat, and straight through porting for bidirectional, high capacity flow and easy roddable cleaning on the block valves

Blow-out proof stem provides a secondary stem seal in the full open position

FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

All stems are 316 Stainless Steel

All stem threads are rolled for strength and ease of operation

One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

Slotted spring pin to prevent accidental loosening

Vinyl dust caps for bonnets and stems (non-packing)

Patented body-to-bonnet, metal-to-metal seal is designed to significantly increase the pressure

ORDERING INFORMATION

| SERIES | 5 | 5-valve | ||||

| SEATS | 0 | Hard seat | 1 | Soft seat/tip | ||

| PROCESS TYPE | 3 | Natural gas flow | ||||

| CONNECTION | 0 | 1/2″ NPT or flange | ||||

| VALVE TYPES | MFC | Flange-Female, Steel | MFS | Flange-Female, Stainless Steel | MMC | Flange-Flange, Steel |

| FFC | Female-Female, Steel | FFS | Female-Female, Stainless Steel | MMS | Flange-Flange, Stainless Steel |

ORDERING INFORMATION – Additional Options

| BODY CONFIGURATION | FP | Flare Pattern™ | ||||||

| SOFT SEATS | PK1 | PEEK | KF1 | PCTFE | ||||

| PACKINGS† | P1 | PTFE | P2 | Graphite ** | ||||

| STEM TIPS | T1 | Non-rotating (316 stainless)** | T4 | PEEK*** | T7 | Ball (ceramic)** | T10 | Regulating Acetal*** |

| T2 | Acetal*** | T5 | Ball (440C stainless)** | T8 | Ball (Monel)** | T11 | Regulating PTCFE*** | |

| T3 | PTCFE*** | T6 | Ball (carbide)** | T9 | Non-rotating regulating (316 Stainless)** | T12 | Regulating PEEK*** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Perfluoroelastomer) | NB1 | NBR | ||

| HANDLES | HL1 | 1-13/16″ Mini “T” | HL4 | 1-3/8″ Phenolic | ||||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For 5030 only.

*** For 5130 only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are isolation “T” handles (HL2) and equalizing & vent 1-3/8″ mini “T” handles (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, handles on the 5130-MFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.

Reviews

There are no reviews yet.